Beyond the Basic Weighment

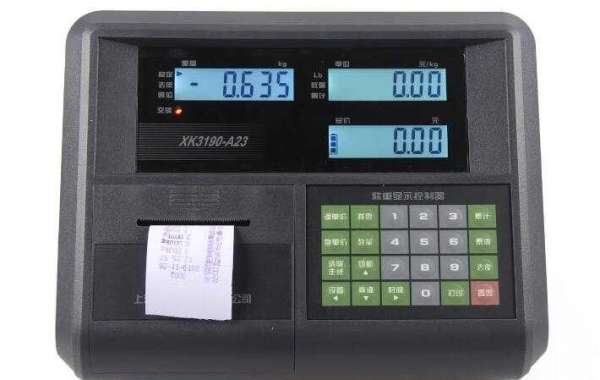

Modern weighing display instruments are no longer limited to simply displaying weight values. Software integration has expanded their capabilities dramatically. Here's how:

Data Acquisition and Management: Sophisticated software allows for real-time data capture, storage, and analysis. This data can be utilized for various purposes, including quality control, inventory management, and production optimization.

Connectivity and Integration: Weighing instruments can now seamlessly integrate with other systems and devices, such as ERP, MES, and PLCs. This integration enables automated data transfer, reducing errors and improving overall efficiency.

Advanced Calculations and Functions: Complex calculations, such as density determination, percentage weighing, and statistical process control (SPC), can be performed directly on the weighing instrument. This saves time and reduces the risk of manual calculation errors.

User Interface Enhancements: Intuitive touchscreens and user-friendly interfaces have replaced complex button-based controls. This makes the instruments easier to operate and reduces training requirements.

Remote Monitoring and Control: Software enables remote access to weighing instruments, allowing for real-time monitoring, troubleshooting, and configuration changes.

Case Studies: Real-World Applications

To illustrate the impact of software advancements, let's consider a few examples:

Food and Beverage Industry: Weighing instruments equipped with advanced software can track ingredient quantities, calculate nutritional information, and ensure product consistency. This helps maintain quality standards and comply with regulatory requirements.

Pharmaceutical Industry: In this highly regulated industry, precise weighing is critical. Software-driven weighing instruments can track batch information, generate audit trails, and ensure compliance with Good Manufacturing Practices (GMP).

Logistics and Shipping: Weighing systems with advanced software can optimize load distribution, calculate freight charges accurately, and generate shipping documents automatically. This improves efficiency and reduces costs.

The Future of Weighing Display Instruments

As technology continues to evolve, we can expect even more groundbreaking developments in weighing display instruments. Artificial intelligence (AI) and machine learning have the potential to revolutionize the industry by enabling predictive maintenance, automated quality control, and intelligent decision-making.

In conclusion, software advancements have transformed weighing display instruments from simple measuring devices into powerful tools that drive efficiency, accuracy, and productivity across various industries. As technology continues to progress, we can anticipate even more innovative solutions that will shape the future of weighing.