Desulfurization is a pivotal procedure involved in the elimination of sulfur compounds from diverse substances. Its significance lies in upholding both environmental stability and industrial effectiveness. Sulfur compounds are commonly found in sources such as fossil fuels, industrial residues, and natural reserves. The discharge of these compounds can result in detrimental consequences like air pollution, acid rain, and environmental deterioration. Among the groundbreaking approaches gaining recognition in the realm of desulfurization, hydro cavitation stands out. This piece will explore several desulfurization techniques, highlighting the particularly promising method of hydro cavitation.

Common Methods of Desulfurization

- Hydrodesulfurization (HDS)

This method is extensively utilized in the petroleum industry to remove sulfur compounds from crude oil and its derivatives. The process involves reacting the sulfur compounds with hydrogen gas at high temperatures and pressures in the presence of catalysts. This results in the conversion of sulfur compounds into hydrogen sulfide, which can be further processed or captured.

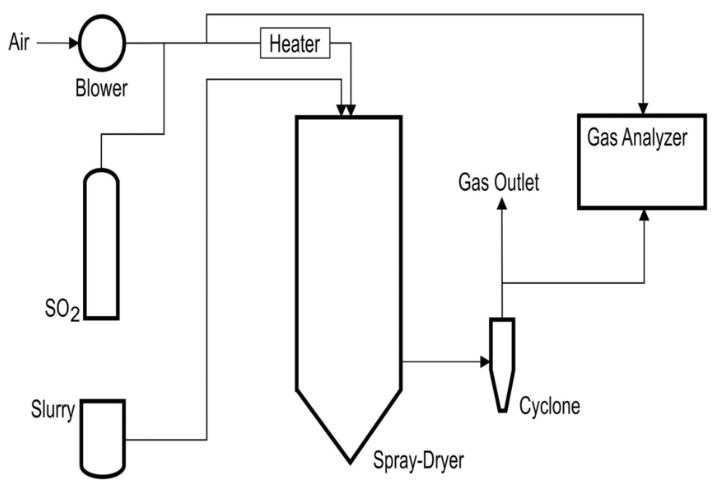

- Flue Gas Desulfurization (FGD)

FGD is commonly applied in power plants and industrial facilities that burn fossil fuels. It involves the removal of sulfur dioxide (SO2) from flue gases before they are released into the atmosphere. Various FGD technologies, such as wet scrubbing, dry scrubbing, and spray drying, enable the capture of sulfur dioxide using chemical reactions or physical processes.

- Biological Desulfurization

Certain microorganisms have the capability to metabolize sulfur compounds. Biological desulfurization, also known as biodesulfurization, harnesses the activity of these microorganisms to break down sulfur compounds present in fuels and industrial waste. This method is eco-friendly and can be employed in specific situations.

- Oxidative Desulfurization (ODS)

ODS involves the oxidation of sulfur compounds to form more soluble derivatives that can be easily separated from the main substance. This technique is commonly used for desulfurizing diesel fuels and other hydrocarbon-rich materials.

- Adsorption

Adsorption methods utilize solid materials called sorbents to capture sulfur compounds from gases or liquids. These sorbents have a high affinity for sulfur compounds and can be regenerated for repeated use. Adsorption is often employed in small-scale applications and research studies.

- Catalytic Desulfurization

Similar to HDS, catalytic desulfurization relies on catalysts to facilitate chemical reactions that convert sulfur compounds into less harmful forms. This method finds application in various industries, including petrochemicals and gas processing.

- Hydro Cavitation

As mentioned earlier, hydro cavitation is an emerging technique that utilizes the mechanical forces generated by cavitation bubbles in a liquid to break down sulfur compounds. This method shows promise due to its energy-efficient and environmentally friendly characteristics.

Each of these methods offers distinct advantages and limitations, and the choice of desulfurization technique depends on factors such as the type of material being treated, the desired level of sulfur removal, and the specific industrial application. Ongoing research and technological advancements continue to enhance these methods and drive toward more efficient and sustainable desulfurization processes.

Introducing Hydro Cavitation

Hydro cavitation emerges as a novel desulfurization approach harnessing the power of cavitation, a phenomenon stemming from swift pressure fluctuations resulting in the creation and collapse of minuscule bubbles within a liquid milieu. This sequence triggers the emergence of concentrated elevated temperatures and pressures, instigating chemical transformations that effectively disintegrate sulfur compounds.

Mechanism of Hydro Cavitation Desulfurization

- Bubble Formation: In hydro cavitation, high-pressure water is passed through a specially designed hydrodynamic cavitation reactor. As the high-velocity water enters low-pressure regions, microscopic bubbles form due to the reduction in pressure.

- Bubble Implosion: These bubbles rapidly collapse upon themselves in a process called cavitation implosion. The implosion generates intense shock waves, microjets, and high temperatures and pressures within the collapsing bubbles.

- Chemical Reactions: The extreme conditions created by cavitation implosion promote the breaking of sulfur-carbon bonds in organic molecules, thereby facilitating the conversion of sulfur compounds into simpler and less harmful forms.

Advantages of Hydro Cavitation Desulfurization

Energy Efficiency: Hydro cavitation requires lower temperatures and pressures compared to traditional methods like HDS. This results in reduced energy consumption and operational costs.

Reduced Catalyst Dependency: Unlike HDS, hydro cavitation does not heavily rely on expensive catalysts, making it a cost-effective alternative.

Environmentally Friendly: The process generates less waste and consumes fewer resources, aligning with the growing emphasis on sustainable and green technologies.

Conclusion

Desulfurization is a vital process for mitigating environmental pollution and ensuring industrial efficiency. While traditional methods like hydrodesulfurization and flue gas desulfurization have been effective, the emergence of innovative techniques like hydro cavitation presents a promising avenue for efficient and sustainable sulfur removal. The power of hydro cavitation lies in its ability to harness the forces of cavitation implosion to drive chemical reactions that break down sulfur compounds, making it a valuable addition to the toolkit of desulfurization technologies. As research and development in this field continue, hydro cavitation may play a pivotal role in shaping the future of cleaner and more sustainable industries.