Experimental and Kinetic Modeling Study of 2 Methyl 2 Butene

Abstract

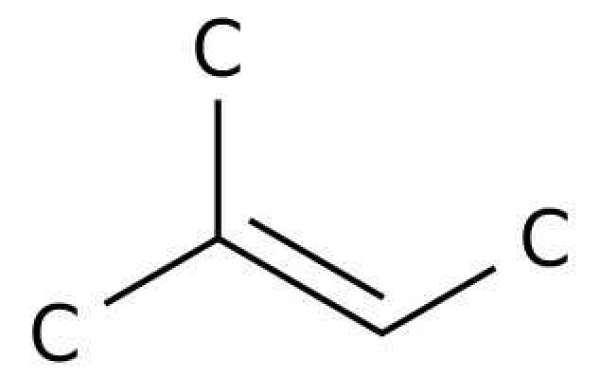

Two experimental studies have been carried out on the oxidation of 2 methyl 2 butene, one measuring ignition delay times behind reflected shock waves in a stainless steel shock tube, and the other measuring fuel, intermediate, and product species mole fractions in a jet-stirred reactor (JSR).These JSR experiments represent the first such study reporting detailed species measurements for an unsaturated, branched hydrocarbon fuel larger than iso-butene. A detailed chemical kinetic reaction mechanism was developed to study the important reaction pathways in these experiments, with particular attention on the role played by allylic C–H bonds and allylic pentenyl radicals. The results show that, at high temperatures, this olefinic fuel reacts rapidly, similar to related alkane fuels, but the pronounced thermal stability of the allylic pentenyl species inhibits low temperature reactivity, so 2M2B does not produce “cool flames” or negative temperature coefficient behavior. The connections between olefin hydrocarbon fuels, resulting allylic fuel radicals, the resulting lack of low-temperature reactivity, and the gasoline engine concept of octane sensitivity are discussed.

Introduction

Chemical kinetic simulations have grown steadily in complexity, accuracy, and impact oncombustion chemistry research, taking a place with chemical theory and advanced, optical experiments as essential tools for probing practical energy systems and understanding fuel oxidation. For many years, experiments and theory generally appeared first and thus motivated subsequent kinetic modeling analysis. This sequence especially characterized development of models for combustion of small molecule fuels such as hydrogen, methane, methanol, propane, and others where often the experimental studies had preceded kinetic models by as much as 20 or 30 years (1). Kinetic modeling is particularly valuable when a combination of new experiments and kinetic modeling can address fundamental processes that have significant impacts on practical combustion problems. The present work concerns oxidation of 2 methyl 2 butene (2M2B), a small unsaturated branched hydrocarbon fuel that, to our knowledge, has not been the subject of previous kinetic modeling or laboratory experimental studies, although it is produced as an intermediate during the combustion of many larger hydrocarbon fuels.

Experiments: Shock Tube

Test mixtures were prepared manometrically in a mixing tank of 3.05 m length made from stainless steel tubing with a 15.24 cm ID. The pressure in the mixing tanks was measured using a Setra GCT-225 pressure transducer (0–17 atm). The mixing tank is connected to the vacuum system and can be pumped down to pressures below 1 × 10–6 Torr. The gases (2 methyl 2 butene [Sigma Aldrich, 99%), O2 (Praxair, 99.999%), and Ar (Acetylene Oxygen Company, 99.999%)] were passed through a perforated stinger traversing the center of the mixing tank to allow for rapid, turbulent mixing. To further ensure homogeneity through diffusion processes, mixtures were allowed to rest for at least 12 h prior to making the first run. No difference in the results was observed for longer mixing times.

Experiments were performed under a constant pressure of 1.06 bar (800 Torr), at a residence time of 1.5 ± 0.1s, at temperatures ranging from 600–1100 K, and for stoichiometric conditions. Some experiments were performed at temperatures as low as 500 K, but little reactivity was observed below 700 K. Helium was used as diluent and the study was performed with a fuel mole fraction of 0.01. The 2 methyl 2 butene, helium and oxygen were provided by Sigma-Aldrich (purity ≥99.0%) and Messer (purity of 99.999% for He and of 99.995 for O2), respectively.