One of the major challenges facing the oil and gas industry is the reduction of sulfur content in fuels. High sulfur levels contribute to air pollution, acid rain, and health hazards when burned, prompting regulators around the world to impose stricter standards on fuel sulfur content. Among the various technologies being explored to meet these challenges, the Ultrasonic Oxidative Desulfurization Plant has emerged as a highly promising and efficient solution.

The Need for Advanced Desulfurization Technologies

Desulfurization, the process of removing sulfur compounds from fuel, is a crucial step in refining to produce cleaner fuels. Traditional methods, such as hydrodesulfurization (HDS), are effective but come with significant drawbacks. HDS operates at high temperatures and pressures, requiring large amounts of energy and expensive catalysts to break down sulfur compounds. This process not only increases operational costs but also has a sizable environmental footprint due to its energy consumption and associated emissions.

As stricter environmental regulations push for lower sulfur content in fuels, oil refineries are in search of more cost-effective and environmentally friendly desulfurization technologies. This is where the Ultrasonic Oxidative Desulfurization Plant steps in.

How Ultrasonic Oxidative Desulfurization Works

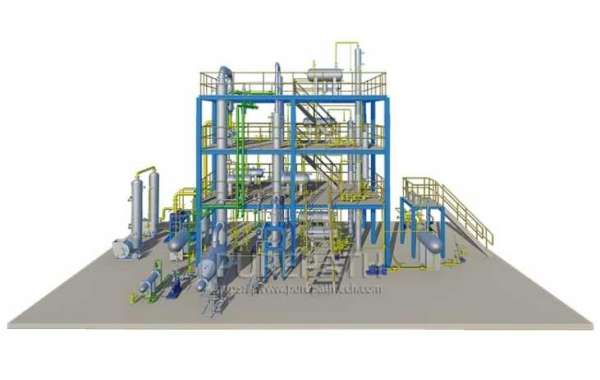

The Ultrasonic Oxidative Desulfurization (UOD) process leverages high-frequency ultrasonic waves to enhance the chemical reactions needed to remove sulfur compounds from fuels. This method works at significantly lower temperatures and pressures compared to traditional methods, making it a more energy-efficient and cost-effective solution.

Ultrasonic waves generate microscopic bubbles in the fuel, which collapse with immense force, creating localized high temperatures and pressures. These conditions trigger oxidative reactions that convert sulfur-containing compounds into sulfones, which can be easily separated from the fuel. The result is a cleaner fuel with significantly reduced sulfur content.

The Ultrasonic Oxidative Desulfurization Plant is capable of processing a variety of feedstocks, including crude oil, diesel, and other petroleum-based products. This flexibility allows it to cater to the diverse needs of different refineries and oil processors, making it an attractive option for the industry as a whole.

Benefits of Ultrasonic Oxidative Desulfurization

One of the key advantages of the Ultrasonic Oxidative Desulfurization Plant is its energy efficiency. Because the UOD process operates at lower temperatures and pressures, it requires significantly less energy compared to traditional desulfurization techniques like HDS. This reduction in energy consumption translates into lower operational costs and a smaller carbon footprint, making it an environmentally friendly alternative.

Moreover, the UOD process eliminates the need for expensive catalysts typically used in HDS. This not only reduces costs but also simplifies the desulfurization process, making it more accessible for refineries looking to upgrade their systems without large-scale overhauls.

Another major benefit of the Ultrasonic Oxidative Desulfurization Plant is its ability to be integrated with existing desulfurization units. By enhancing the performance of current desulfurization infrastructure, UOD can help refineries meet even stricter sulfur regulations while avoiding the need for completely new installations.

Environmental and Economic Impact

In addition to its operational benefits, the Ultrasonic Oxidative Desulfurization Plant offers significant environmental advantages. Lower sulfur emissions from fuels lead to a reduction in air pollution and the formation of acid rain, which are both critical global concerns. Cleaner-burning fuels also contribute to better public health outcomes, particularly in urban areas where air quality is often compromised by vehicle emissions.

From an economic perspective, investing in UOD technology can lead to long-term savings. The lower energy requirements and reduced need for expensive catalysts contribute to more sustainable operations. Additionally, as governments around the world continue to tighten sulfur regulations, early adoption of advanced desulfurization technologies like UOD can give refineries a competitive edge by ensuring compliance with future standards.

Conclusion

The Ultrasonic Oxidative Desulfurization Plant is poised to become a key technology in the future of cleaner fuel production. Its ability to deliver high-efficiency sulfur removal with lower energy consumption, combined with its environmental benefits, makes it an attractive option for refineries looking to meet modern regulatory demands. As the industry continues to evolve, adopting innovative solutions like UOD will be essential for producing cleaner, greener fuels while maintaining operational efficiency and cost-effectiveness. For refineries and oil processors seeking a sustainable path forward, investing in Ultrasonic Oxidative Desulfurization Plant technology is a step in the right direction.