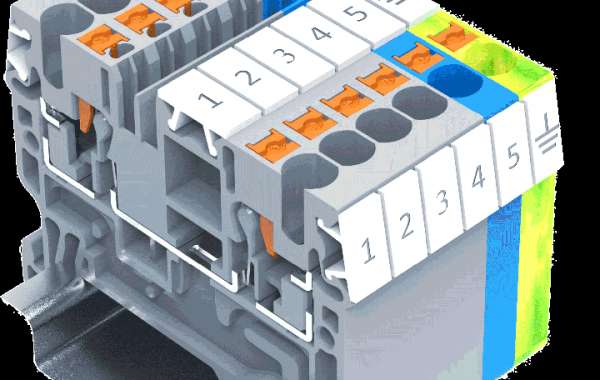

Splice connectors—also commonly known as butt connectors, butt splices, or crimp connectors—have been in use for decades and remain an important component in 12-volt Electrical Terminal Blocks. Here are some basics to help you select and use them.

What Is a Butt Connector?

At its most basic, a butt splice is a fast, effective way of connecting and securing the ends of two wires without having to solder them. While soldering has its advantages, the time and cost involved can be prohibitive. In addition, the high heat used in soldering introduces the risk of injury. A butt connector is simpler, faster, and arguably safer to use. Even mechanics and technicians new on the job can quickly and easily fit both wire ends into each end of a butt connector and crimp for a secure connection.

Conductive Materials

Butt connectors come with different types of conductors, most commonly copper or steel.

Tin plated copper is the standard conductive material used in a wide range of splice connectors. Relatively inexpensive, tin plated copper works well for many applications. It is highly conductive, easily crimpable, and anti-corrosive.

Nickel plated steel, a more expensive and less malleable material, is the preferred conductor for high-temperature applications.

Insulated and Non-Insulated

Many butt connectors come without an insulating jacket and are a cost-effective way to complete a wide range of automotive electrical wiring projects. Others are available in various types of insulating jackets such as vinyl and nylon.

Vinyl is the low-cost insulation standard, appropriate for use in many applications and in high and low humidity environments. However, it tends to harden or crack at high or low temperatures.

Nylon is more expensive but has certain advantages: It is a stronger material, more durable in high and low temperature extremes, and more flexible and pliable for crimping. Terminal Block Manufacturers’product also typically comes in in transparent or semi-transparent form, which allows for easy inspection of the wire connection once terminated.

Buscar

entradas populares

-

퍼스트카지노에 대한 가장 중요한 개념 중 일부

Por Engkalpol

퍼스트카지노에 대한 가장 중요한 개념 중 일부

Por Engkalpol -

What Are The Well Known Facts About Online Casino Games Malaysia

Por Arnyen

What Are The Well Known Facts About Online Casino Games Malaysia

Por Arnyen -

Watch Online Pearl Harbor 720p Watch Online Dvdrip Bluray Dubbed

Por flexelsrelow

Watch Online Pearl Harbor 720p Watch Online Dvdrip Bluray Dubbed

Por flexelsrelow -

Navigating Turkey's E-Visa Process for Egyptian Travelers: A Comprehensive Guide

Por Joshpom Perter

Navigating Turkey's E-Visa Process for Egyptian Travelers: A Comprehensive Guide

Por Joshpom Perter -

Gründe, warum Sie eine Digitale Marketing Agentur in Berlin gründen sollten!

Por Lean Port

Gründe, warum Sie eine Digitale Marketing Agentur in Berlin gründen sollten!

Por Lean Port

Categorías

- Automóviles y Vehículos

- Negocios y Oportunidades

- Economía y Comercio

- Educación

- Entretenimiento

- Cine y Animación

- Juego de azar

- Historia y Datos

- Estilos de vida

- Servicios

- Noticias y Política

- Pueblos y Naciones

- Animales y mascotas

- Lugares y Regiones

- Ciencia y Tecnología

- Deporte

- Viajes y Eventos

- Contactos

- Esoterismo

- Informatica

- Transportes

- Turismo

- Salud y Belleza

- Construcción

- Otro